If you don't want to raise the engine, and want the oil pan removed you have to remove the crossmember and the midlink, yes. Just back off on the locknuts a turn and stop so you can replace it when you're done without affecting the alignment. Be aware that they have opposite-hand threads...that is, the midlink attaches to both tie rods at the same time.

I would say the right side has right-hand threads, and the left side has left-hand threads. I used a 15-inch adjustable wrench to hold the midlink while I released the lock nuts.

Replacing the oil pan under the vehicle is not fun. You will also need to remove both of the braces on the rear of the block, one of which has the clutch cable going through it. I don't have an automatic, so I can't say what it looks like. Be sure you don't over-tighten the bolts on the pan and make the new gasket get damaged. My oil pan gasket said not to use any chemicals, but I had to use Permatex® to make it stay in place. I put it on the block first.

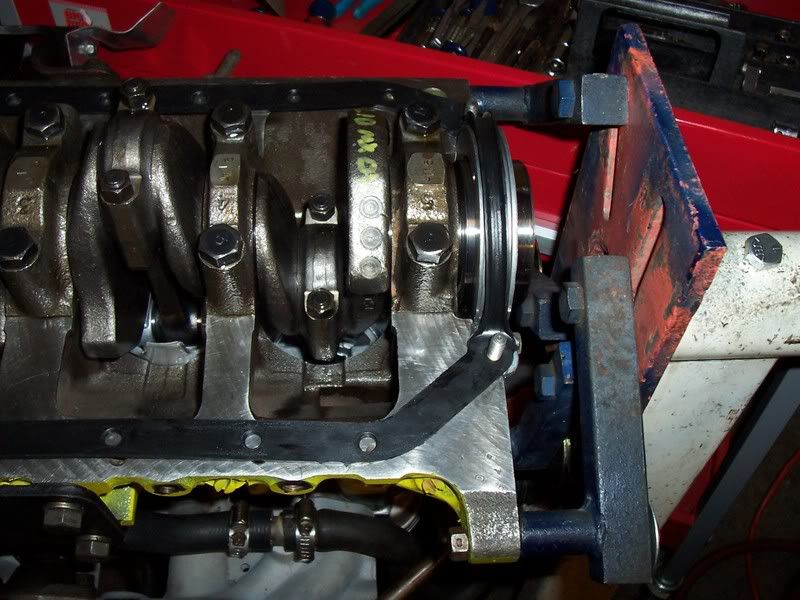

When I had the engine in the shop on a stand, it was a lot better. Especially since I forgot to include the oil pickup tube, and immediately had to do it over!!!

PS- That wasn't a dumb question; the manual describes it.

Here's a few views...

The front; remember to apply sealant at the points where the steel block meets the aluminum brackets/The rear

The oil pan/Herein lies the problem; see how the gasket doesn't line up perfectly with the holes?

That's why I had to use Permatex®, because the rubber gasket wouldn't stay where I wanted it

Much easier upside down on an engine stand!!!/Notice the even line of the gasket

No protrusions, or bulging